Open Water Well Entry Solutions

Open Water Well Entry Solutions

Utilising lightweight work vessels is an efficient and cost-effective solution to meet the maintenance and end-of-life operational demands of subsea wells. The key enabler to meeting this demand is the provision of compact, lightweight, high-performance subsea intervention packages. They need to facilitate ease of deployment with a high level of security and functionality to perform efficient well intervention operations from these types of work vessels.

To answer this demand, Interventek’s Revolution valve technology has been packaged in an Open Water assembly that provides high structural integrity suitable for the environment. Alongside its best-in-class features, it is a lighter, more compact and more efficient shear and seal solution than any other comparable device on the market. It is particularly suited to the cost challenges of end-of-life applications.

Interventek’s open water system solutions can include a variety of components alongside the Open Water Valve. A ball valve can be added to provide the flexibility of bi-directional sealing and a retainer valve ensures the contents of the riser is contained. High set lubricator valves facilitate the testing of tool strings deployed from the vessel into the well and the design has been adapted to accommodate externally mounted actuators that can be removed for maintenance or changed to suit the system and service requirement.

The low swept volume of hydraulic fluid, that is a trademark of the Revolution valve, reduces the requirement for bulky accumulation modules, further reducing the size, weight and complexity of the intervention system.

These lower cost, lighter weight well entry solutions are particularly suited to end-of-life applications and deployments from lightweight vessels. With modular valve and system components, a wide range of configurations and the ability to interface with 3rd party equipment, our solutions can be tailored to suit a range of projects including intervention, temporary well suspension, P&A and decommissioning. Our open water solutions are field proven, API 17G compliant and available in a range of sizes and working pressures up to 20,000psi.

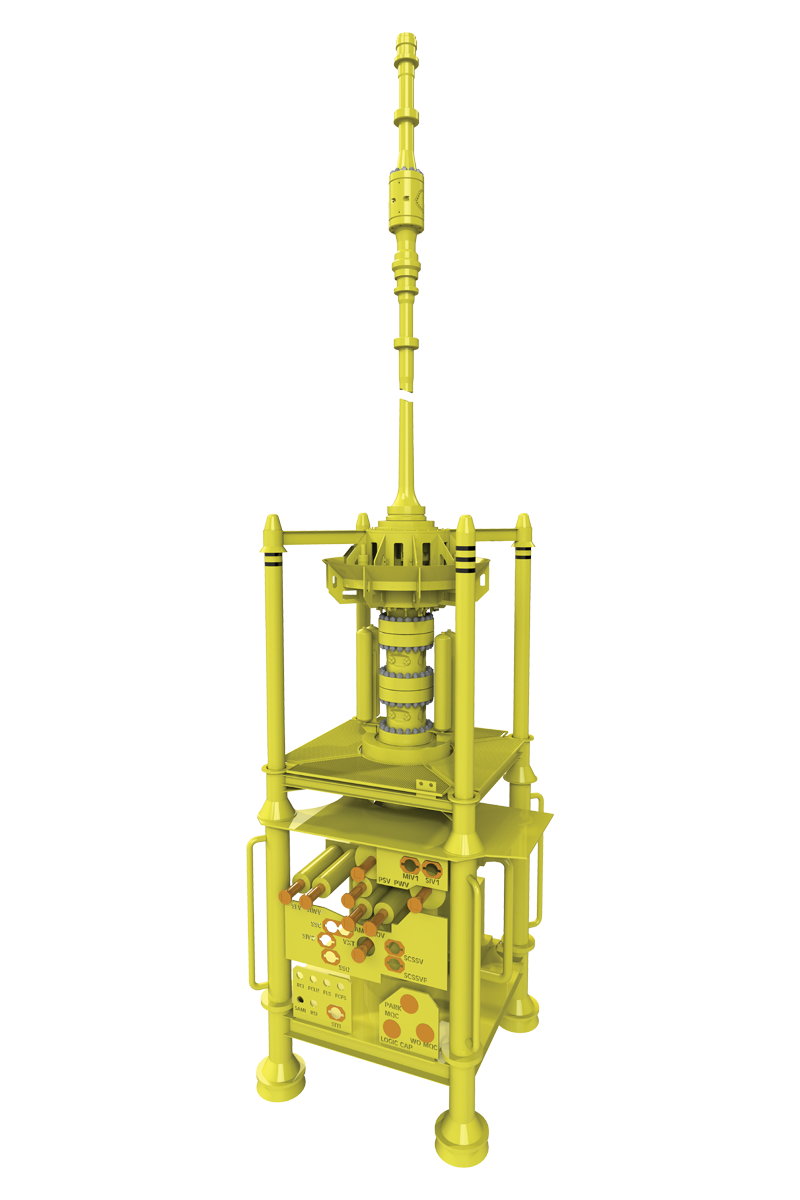

Ultra-Lightweight Intervention System (ULWIS)

Interventek has developed a new ultra-lightweight and compact open-water intervention system (ULWIS), which has been designed to minimise the stress applied to aging subsea Xmas Trees and wellhead infrastructure during operations. The ULWIS is especially suited to reducing the costs associated with well abandonment campaigns by providing operational and deployment flexibility, time-savings from ease of handling and reduced cost of ownership.

Ease of Deployment

In its conventional EDP/LRP configuration the ULWIS utilises a 4-valve arrangement comprising an upper bi-directional ball retainer valve, latch, dual shear and seal valve block and lower bi-directional ball valve.

The entire assembly weighs in at a mere 8T (approx. 10T with control interfaces and frame) and an overall length of less than 3.5m. The frame is 1.6m square, conveniently deployable through the rotary table of a rig and most vessel moonpools. Stacking the system in the derrick of a rig is an option and mobilisation and storage can be achieved using a conventional shipping basket.

Applications

Interventek’s unique Revolution valve and actuator design enables the compact and lightweight attributes of the system as well as unrivalled versatility for different well types and applications. As well as being eminently suited to oil and gas well abandonment operations due to its lightweight nature and its cost and efficiency savings, the system also offers a robust solution for intervening in subsea carbon capture wells. The ULWIS can be built from exotic materials that are resistant to extreme well conditions at a highly competitive price.

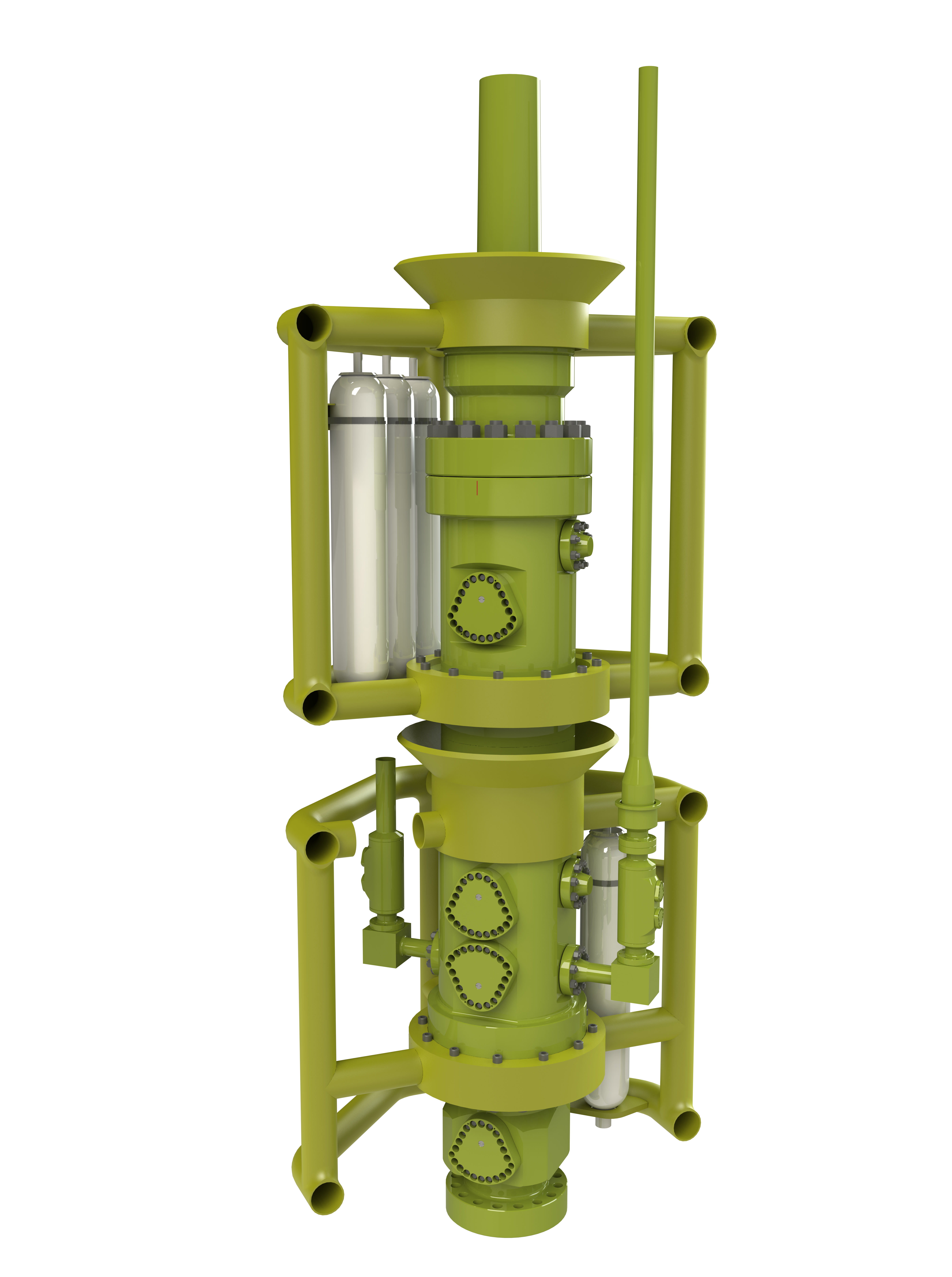

Bore Selector

If a monobore riser or riserless system is used for subsea well intervention but access to both the production bore and the annulus is required, then a return trip to surface is usually necessary to re-align the toolstring. This is a costly operation from a rig or a vessel so a compact and lightweight technology which allows for dual bore or selective bore access in a single trip will provide significant operational cost savings.

Dual Bore Access

Interventek has developed a Dual Bore Selector which provides access to either the main 5-1/8” production bore or the 2-1/16” annulus in a traditional vertical xmas tree. The Bore Selector uses a flapper which can

be selectively positioned to isolate access to either the production bore or the annulus bore. A 2-1/16” bi-direction ball valve is also included in the annulus access route to enable circulation of fluids.

Lightweight and Compact

The Bore Selector weighs less than 4T and is just 1.65m in length. It is positioned between the Tree Running Tool and the Lower Riser Package and can be operated in two ways.

Operation

An ROV interface allows manual bore selection with external indicators to confirm flapper and ball valve positions, or alternatively a surface-controlled hydraulically actuated system can be included.

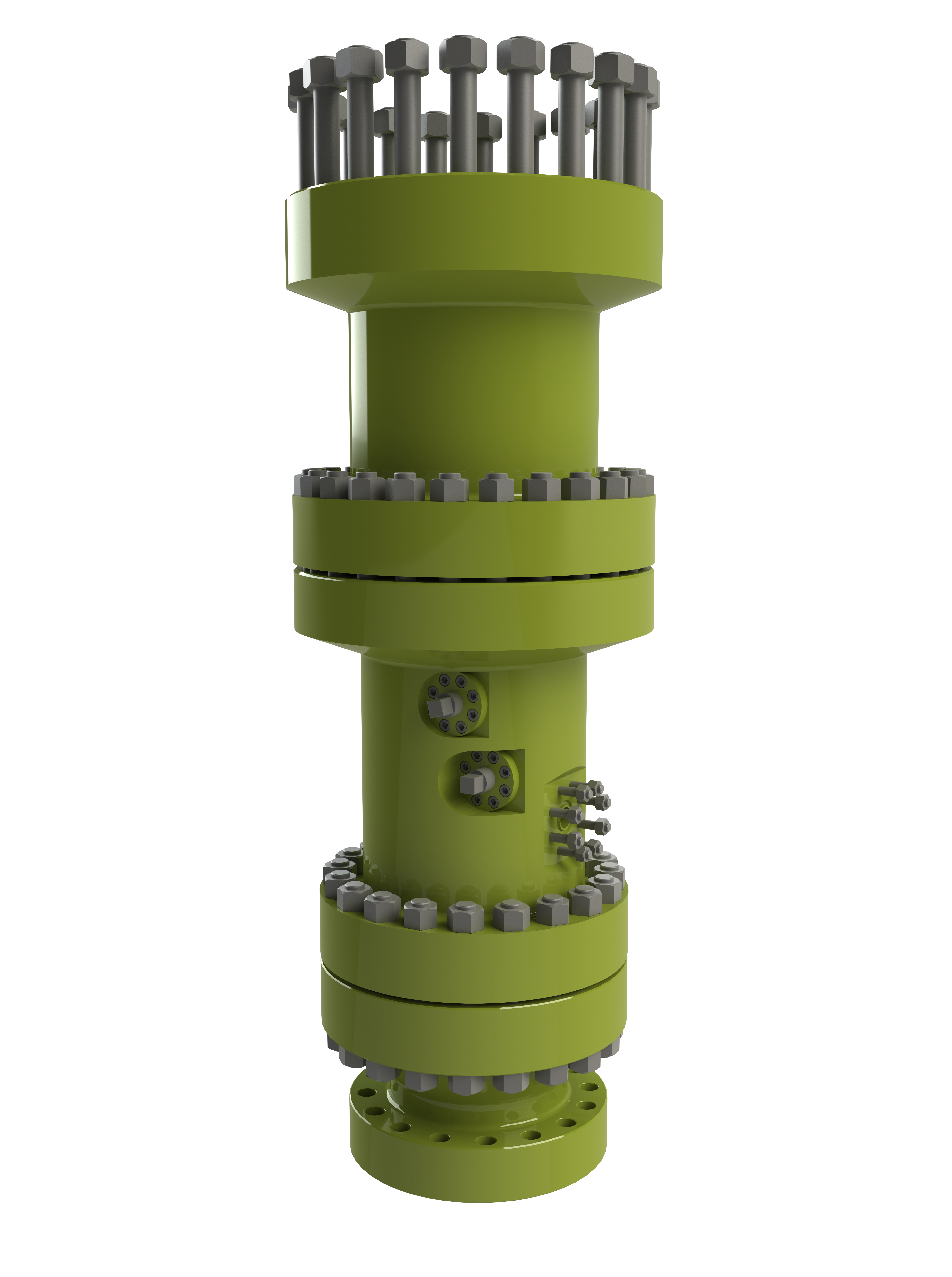

Subsea Capping Stack

Our open water equipment can also be deployed as a fast incident response measure. For emergency response well containment, our Capping Stack is 50% lighter, smaller and easier to mobilise to site quickly, as well as easier and faster to deploy compared to other available solutions. The lightweight and compact nature of this equipment makes it ideally suited to contingency tree-on-tree installation during well entry operations.

This API 17G compliant configuration contains a hydraulically operated, compact shear and seal revolution valve designed with high cutting performance and reliable post-cut sealing to replace the use of a ram. The valve will cut all common slickline, e-line and braided cable grades plus coiled tubing rated to 130ksi min yield and 2.875" x 0.156" wall thickness. Suitable for sour service deployment, the valve offers recirculation capability, demountable actuators to facilitate in-situ maintenance and is rated to 15,000 psi.