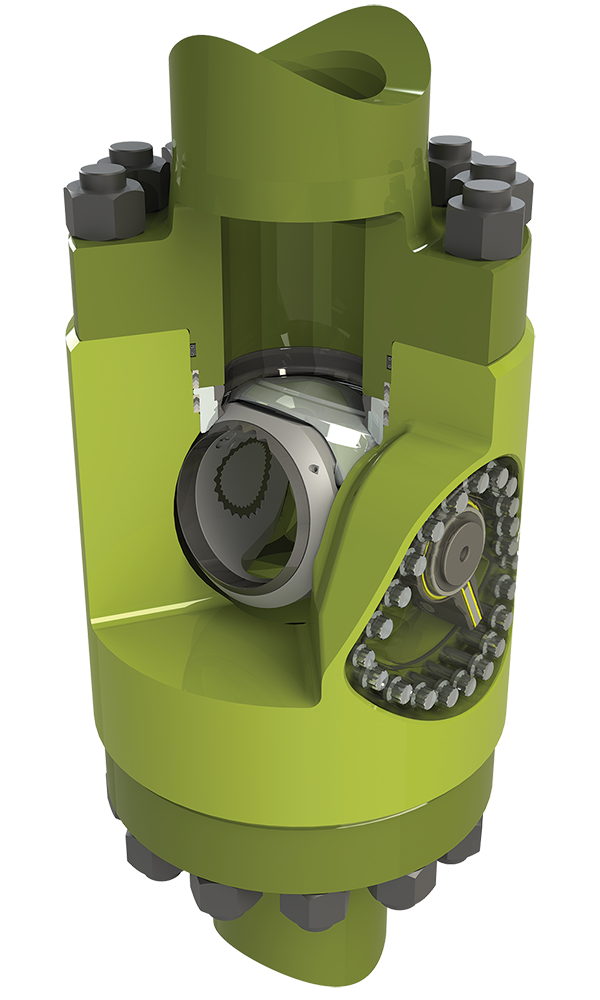

In-Riser Revolution Valve

The compact nature of the Revolution valve and its actuator components is extremely beneficial for in-riser applications. A short valve is more easily accommodated to sit below drilling BOPs which have irregular shear ram spacing and can often be restrictive.

The compact internals leave substantial material available in the body to be utilised for preloaded end connections, such as a flange. These connections are mechanically superior to non-preloaded connections and extremely desirable where cyclic loading is possible.

Features

Benefits

Fewer, simpler components and stronger fit-for-purpose design

- Minimises cost

- Improves reliability

- Reduces lead time

Separates cutting and sealing components in a single device

- Minimises cost

- Improves reliability

- Reduces lead time

Rotary actuators

- Eliminates binding and maximises cutting torque

External actuators

- Separates controls from the wellbore environment

- Ensures rapid closure

Resilient well bore sealing

- Enables use in high pressure and high temperature applications

- Provides explosive decompression resistance

Compact and lightweight design

- Facilitates installation in short BOP’s

- Allows additional or alternative valve functions to be incorporated

Common flanged connection

- Improves structural integrity including fatigue capacity

- Reduces cost